The number one supporting facility for outdoor lighting should be the outdoor distribution box. We all know that there is a type of distribution box called waterproof distribution box in all categories of distribution boxes, and some customers also call it rain-proof distribution box. In fact, this type of distribution box is mainly used outdoors to prevent some harsh Weather, first of all, needless to say that the waterproof distribution box must have the function of dust proof and waterproof, and also need to have the function of acid and alkali resistance, and the protection level requirements are also particularly high, and it needs to reach IP66.

Want to know the application of common equipment and materials for outdoor stainless steel in-ground lighting? What are the differences between the distribution box materials used in outdoor lighting?

In the early stage of the plan, we have to consider the installation location and electricity load of the distribution box. In the previous project, due to insufficient consideration, the construction site was often frustrated (the high-rise of more than 300 meters, the lighting distribution box was set on the negative floor, and most of the lamps and lanterns were frustrated. Centralized on the roof, and there are more than a dozen high-power searchlights, in the early stage of the project, it can be proposed to set the lighting distribution box on the roof).

Selection of distribution box shell materials: Generally, different materials are selected from the use environment and cost of the product; the current mainstream in the market is mainly metal materials, and the common materials are as follows:

Cold-rolled sheet SPCC:The surface treatment adopts electroplating and baking paint, which is low in cost and easy to form. The material thickness is less than or equal to 3.2mm. It is currently the most widely used, accounting for about 80% of the market.

Hot-rolled sheet SHCC: The surface treatment adopts electroplating and paint parts, which is low in cost, but difficult to form. The material thickness is ≥3.0mm, and flat parts are mainly used.

Copper: The surface treatment is nickel-plated, chrome-plated, or not treated, and the cost is high.

Stainless steel: The surface is not treated, the cost is high, but it is characterized by good anti-rust function and more durable, especially suitable for use in outdoor environments.

Aluminum plate: The surface treatment generally uses chromate and oxidation (conductive oxidation, chemical oxidation), which is expensive, but it has the characteristics of high temperature resistance, corrosion resistance, and good insulation, so it is relatively safer.

Aluminum profile: a material with a complex cross-sectional structure, which is widely used in various sub-boxes. The surface treatment and performance are the same as the aluminum plate.

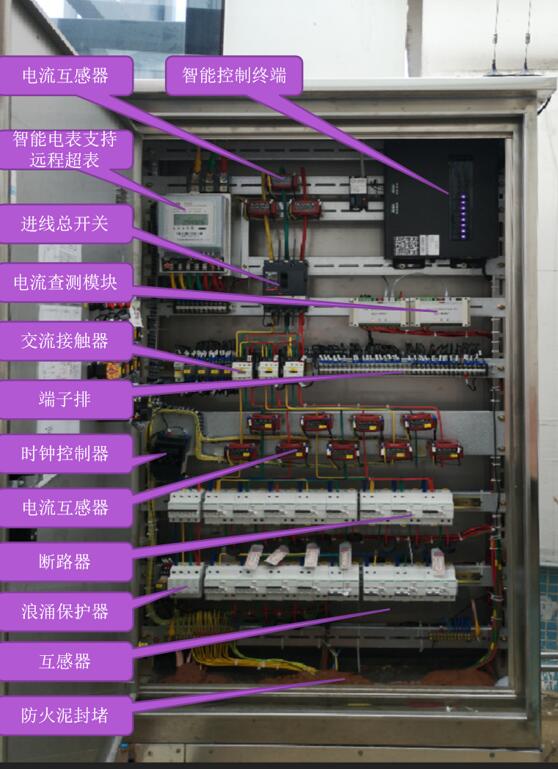

When installing the distribution box on the outdoor ground, the protection level should not be lower than IP54, and the foundation should be no less than 300mm above the ground. The following picture shows the construction drawing of the distribution box:

The pictures as below are a real picture of the distribution box. If you look carefully, there are more antennas and compound eye photo receptors on it.

Post time: Sep-28-2022